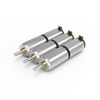

Coreless Gear Motor

High Performance Low Consumption Coreless Gear Motors

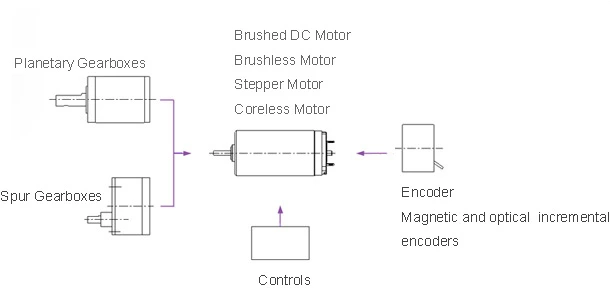

Coreless DC gear motor is made up two parts, precision gearboxs and a coreless dc motor.

Combination: Precision Gearboxes,Drive Electronics and Encoders

Customization Range:

- Additional voltage types

- Connecting cables (PTFE and PVC) and connectors

- Configurable shaft length and second shaft end

- Modified shaft dimensions and pinion configurations such as flats, gears, pulleys and eccenters

- Extended temperature range

- Vacuum compatibility (e.g., 10-5 Pa)

- Modifications for high speed and / or high load applications

- Modifications for motors with increased electrical or mechanical tolerance requirements

Configure Your Drivers

| Model | Diameter | Voltage Range | Max.Transmittable Power | Rated Speed Range | Max.Continuous Torque | Reduction Ratio | |||

|---|---|---|---|---|---|---|---|---|---|

|

6 mm Coreless Gear Motor (PD) PD006006 | 6 mm | 3-12 V | 0.2 W | 4-1563 rpm | 0.25 Nm | 4-1296 | ||

|

6 mm Coreless Gear Motor (MD) MD006006 | 6 mm | 3-12 V | 0.2 W | 4-1563 rpm | 0.025 Nm | 4-1296 | ||

|

10 mm Coreless Gear Motor (PD) PD010010 | 10 mm | 3-12 V | 0.2 W | 17-3917 rpm | 0.13 Nm | 3-809 | ||

|

10 mm Coreless Gear Motor (MD) MD010010 | 10 mm | 3-12 V | 0.2 W | 17-3719 rpm | 0.2 Nm | 3-809 | ||

|

12 mm Coreless Gear Motor (PD) PD012012 | 12 mm | 3-24 V | 0.18 W | 6-1875 rpm | 0.049 Nm | 4-1296 | ||

|

12 mm Coreless Gear Motor (MD) MD012012 | 12 mm | 3-24 V | 0.21 W | 6-1875 rpm | 0.0294 Nm | 4-1296 | ||

|

16 mm Coreless Gear Motor (PD) PD016016 | 16 mm | 3-24 V | 2 W | 6-1875 rpm | 0.3 Nm | 4-1296 | ||

|

16 mm Coreless Gear Motor (MD) MD016016 | 16 mm | 3-24 V | 2 W | 6-1875 rpm | 0.5 Nm | 4-1296 | ||

|

20 mm Coreless Gear Motor (PD) PD020020 | 20 mm | 3-24 V | 1.59 W | 6-1875 rpm | 1.0 Nm | 4-1296 | ||

|

20 mm Coreless Gear Motor (MD) MD020020 | 20 mm | 3-24 V | 1.59 W | 6-1875 rpm | 1.9 Nm | 4-1296 | ||

|

22 mm Coreless Gear Motor (PD) PD022022C | 22 mm | 3-24 V | 0.5-4.5 W | 6-1875 rpm | 0.8 Nm | 4-1296 | ||

|

22mm Coreless Gear Motor(MD) MD022022C | 22mm | 3-24V | 0.5-4.5W | 6-1875rpm | 1.5Nm | 4-1296 | ||

Fit Customer Requirements

Our Products

From off-the-shelf gear motor, components to fully validated and tested complex mechanisms, choose our gearbox with dc motor inline, encoder, controller, and drive systems partner you can trust.

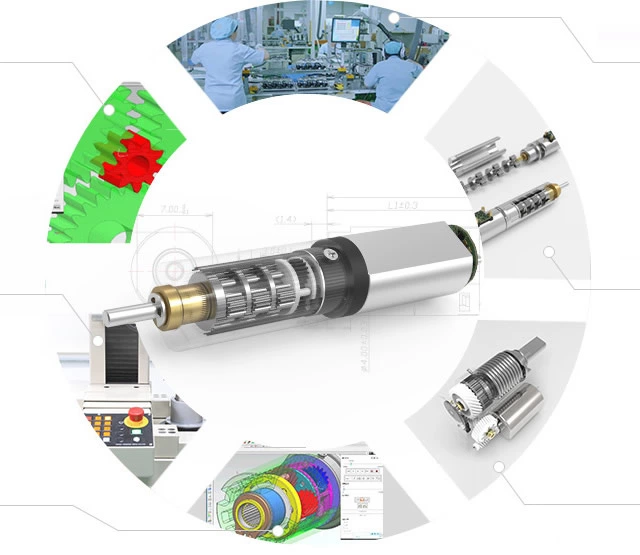

Planetary Gears

ZHAOWEI developes high performance modular gearheads to complement each of its motor technologies.

From high torque planetary technology in a variety materials, to low backlash spur gears, ZHAOWEI has the right solution.The all metal or plastic input-stage geartrain assures extremely quiet running.

Motors and Drive Electronics

Iron-core, coreless and brushless DC motor technologies in a wide range of form factors and sizes, with off the shelf sampling.

For higher positioning and speed control, ZHAOWEI provides a wide range of encoders and controllers to combine with the DC-, brushless, and stepper motors

Custom Assemblies

Shaft: Length, Diameter, Type D, Thread.Winding: Wire Diameter, Number of Turns, Temperature Range.

Bearing: Rolling Bearing, Plain Bearing.

Electrical Connection: Lead Length, Size, Material, Connector Specification. Flange: Mounting Boss, Thread, positioning locking screw hole.

Output element: pinion, pulley

According to the needs of different customers, ZHAOWEI can change the output parts structure, internal process parameters, electrical connection, and other factors (for example heterosexual shaft, high-speed bearing, flange thread connection, special cable, etc.) You bring great convenience and deliver the products you need on-time more reliably and efficiently.

From Zero to N Complete products Solutions

01 Professional Solutions

ZHAOWEI professional R&D team provides market-oriented and customer-based options in order to offer cost-effective solutions according to customer needs.

03 Exclusive Design

ZHAOWEI offers customizable services If standard products do not meet customers needs; we can modify the standard product or develop new products to meet specific needs.

05 Automated Production

ZHAOWEI owns more than hundred automated production lines which provide high-quality, high-efficiency and high-stability in mass production.Standard products delivered in 15 daysand customizable products delivered in 30 days.

02Product Options

ZHAOWEI is able to accurately and effectively meet any challenging orders with prototyping and rapid product design implementation and to provide best solutions for customers.

04Standard Gearbox

ZHAOWEI has hundreds of thousands of sets of motor molds covering a wide range of micro motor and gearbox products, which enables customers to exactly get expected products from an off-the shelf solution

06 Follow-up Services

ZHAOWEI professionally trained after-sales service team owns rich project management experience to follow up timely of customer demands.

Micro dirves are widely used in all walks of life

you can provide you product requirements to our marketing and sales staff,and we will select or design suitable combinations

Decades of R&D and design teams

From high torque planetary technology in a variety of materials to low backlash spur gears, ZHAOWEI has the right solution. The all-metal or plastic input-stage geartrain assures extremely quiet running.

ZHAOWEI gearboxes combine with Iron-core, coreless, and brushless DC motor technologies in a wide range of form factors and sizes, with off-the-shelf sampling. For higher positioning and speed control,ZHAOWEI provides a wide range of encoders and controllers to combine with the DC-,brushless, and stepper motors and ZHAOWEI develops high-performance modular gearheads to complement each of its motor technologies.