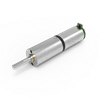

Micro Brushless Gear Motor

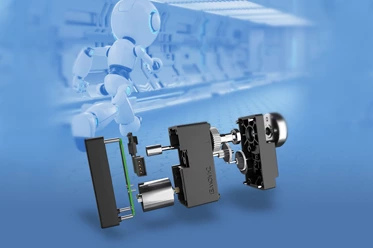

Brushless dc motor (BLDC motor) has the characteristics of low interference, low noise and long life, and has become a widely used product. Based on its excellent performance, it is combined with a high-precision planetary gearbox, which greatly improve the torque of the motor and reduce the speed, suitable for many application fields.

According to the different materials of gearbox, we distinguish metal brushless gear motor and plastic gear motor, metal brushless gear motor has a higher torque; Its unique design of BLDC Gear Motor from ZHAOWEI allows for several key benefits:

- Compact size, Low noise

- Wide range of voltages you can choose from

- Diameters as small as 12 mm

- Rated speed as low as 4rpm

- Torque up to 7845.29 mNm

- High torque, low Speed

- Ability to withstand harsh environments

- Long service life

Not sure how to select the right brushless gear motor? Click on our overview resources below or contact us. Our team will work with you to develop a right solution.

Standard Brushless Gear Motor

| Model | Diameter | Voltage Range | Max.Transmittable Power | Rated Speed Range | Max.Continuous Torque | Reduction Ratio | |||

|---|---|---|---|---|---|---|---|---|---|

|

12 mm Brushless Gear Motor MD012012 | 12 mm | 3-24 V | 0.25 W | 23-7500 rpm | 300-2,000 gf.cm | 4-1296 | ||

|

16 mm Brushless Gear Motor MD016016 | 16 mm | 3-24 V | 2 W | 6-1875 rpm | 5,000 gf.cm | 4-1296 | ||

|

20 mm Brushless Gear Motor MD020020 | 20 mm | 3-24 V | 1.59 W | 6-1875 rpm | 10,000 gf.cm | 4-1296 | ||

|

22 mm Brushless Gear Motor MD022022 | 22 mm | 3-24 V | 4.5 W | 6-1875 rpm | 15,000 gf.cm | 4-1296 | ||

|

24 mm Brushless Gear Motor MD024024 | 24 mm | 3-24 V | 30 W | 4-1150 rpm | 20,000 gf.cm | 4-1296 | ||

|

28 mm Brushless Gear Motor ZWBMD028028 | 28 mm | 3-24 V | 4.5 W | 5-1685 rpm | 40,000 gf.cm | 4-1296 | ||