ZEISS METROTOM

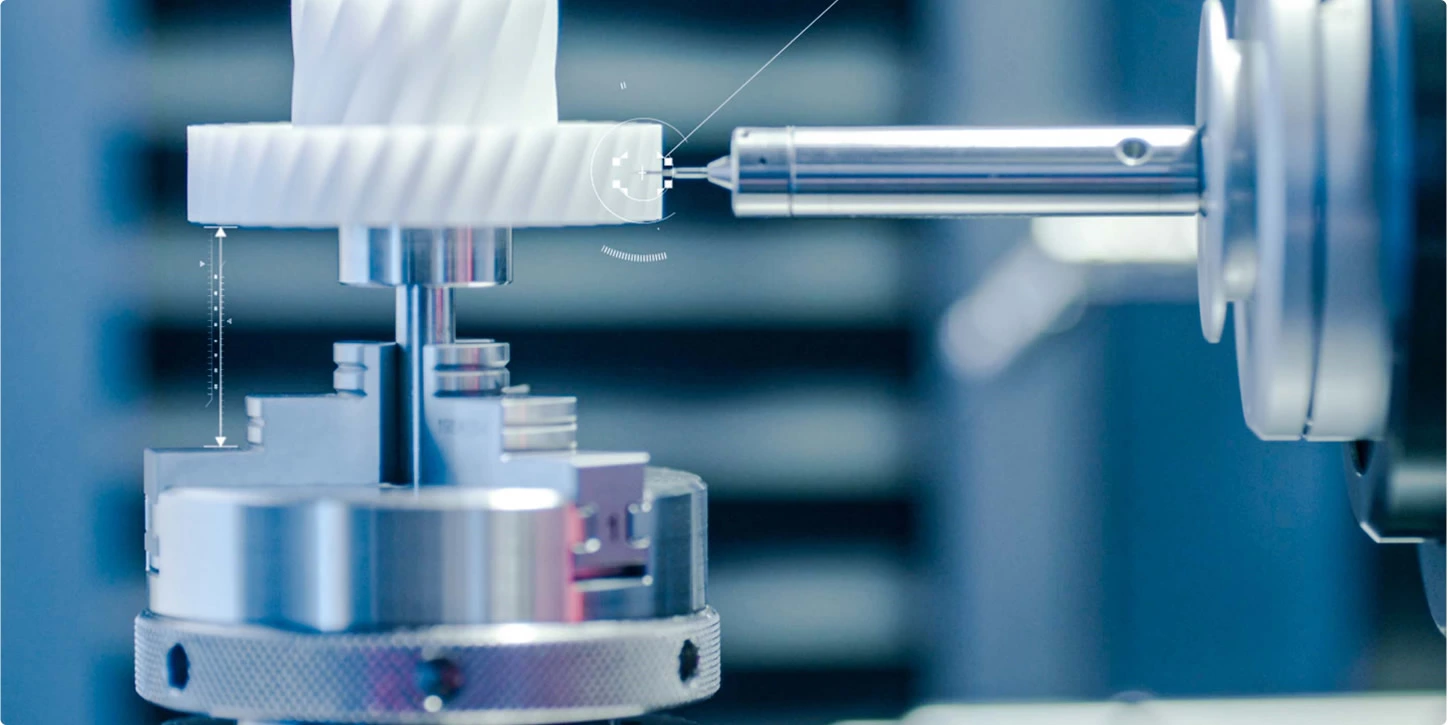

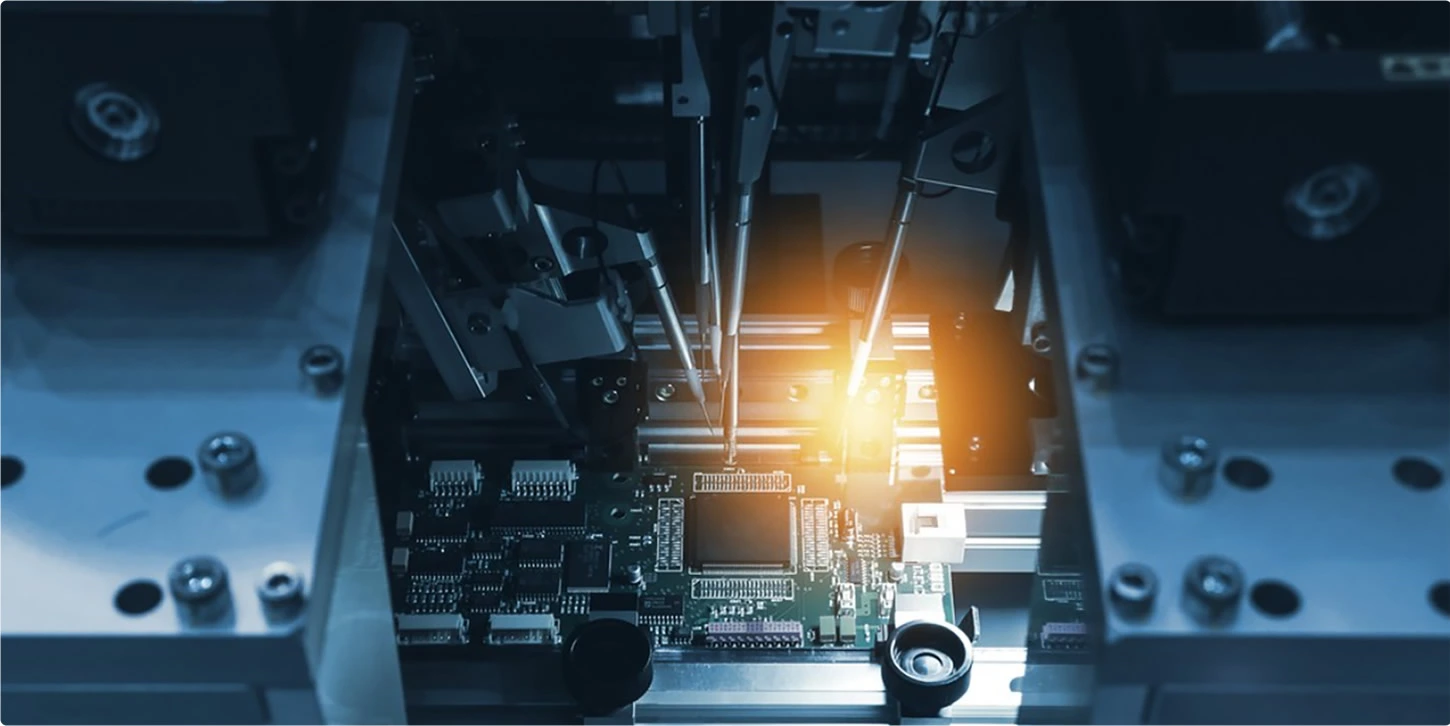

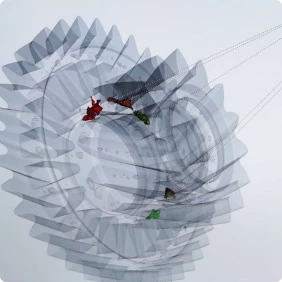

ZEISS METROTOM is a coordinate measuring machine based on CT sensors. It combines functional advantages of X-ray, computed tomography (CT) and coordinate measuring machine (CMM). Industrial CT is positioned for non-destructive inspection, mainly used for internal defects, pores, cracks, impurities and 3D assembly structures, etc., and more importantly for non-destructive geometric measurement, color difference digital-analog comparison, non-destructive internal defects and assembly structure analysis. It has technical advantages, including its authoritative traceability measurement performance, core high-precision components of coordinate measuring machine, CAA error compensation, self-calibration device, intelligent measurement platform, etc.