Gearbox Type

Planetary Gears from ZHAOWEI - Moving the World.

Our whole life is motion, isn’t it? No matter whether in your job or at home, old or young, day or night ... For us at ZHAOWEI, motion is part of our daily business. After all, our planetary gears are an indispensable element when it comes to directing power in the right direction, and that for a great number of industries and applications.

As an experienced manufacturer, we are already an integral part of countless applications in a variety of fields.And as a personal development partner, we combine proven solutions with new ideas, thus making sure that the world of tomorrow will get the drive it deserves. Sounds exciting? We totally agree. Are you up for moving things with us?

Applications for innovative markets

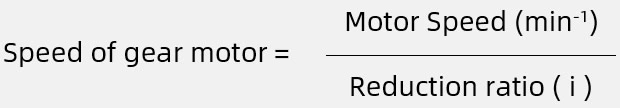

Gearbox (also called gearhead)

A gearhead mechanism capable of increasing torque by reducing the motor speed. An approximate value can be calculated using the following equation. The reduction ratio has been established for each model. Please see the pages of products.

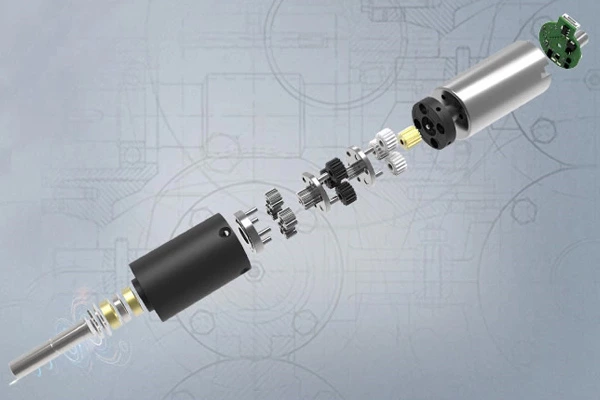

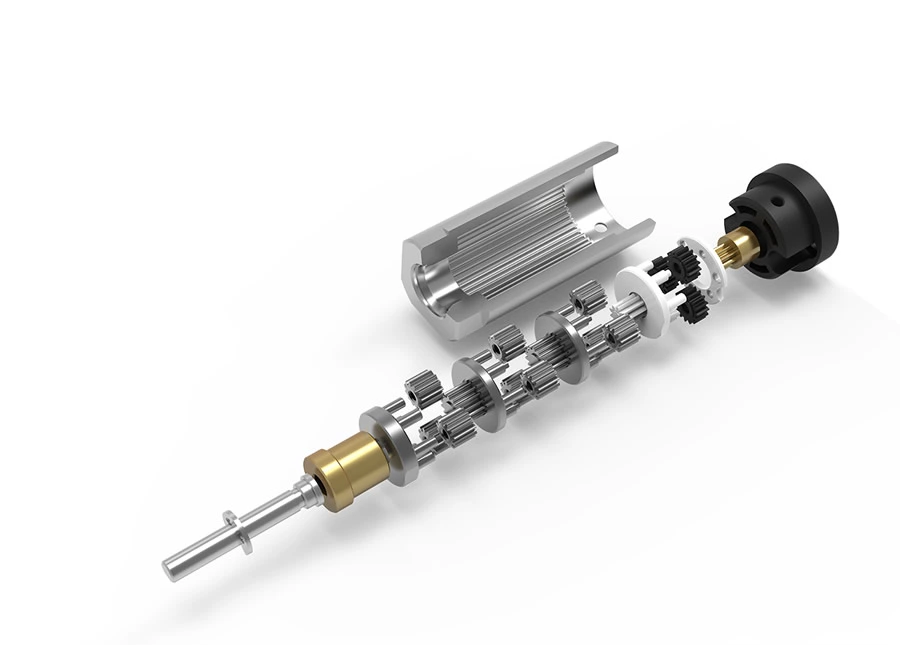

Gearbox Structure

Gearboxes are roughly divided into two types of structures. Planetary Gearhead

Gear Efficiency

Gearheads have mechanical loss (gear meshing, bearing friction, etc.). Generally, for each meshing of one stage, an efficiency of 81% for planetary gears and 90% for spur gears is used in calculation. The gear efficiency, however, varies largely depending on such factors as motor torque and speed therefore is presented as a reference value. When used at a lower torque, the efficiency will drop significantly.

An example of calcuation of efficiency

- Spur gear 3-stage meshing

- Planetary gear 2-stage meshing

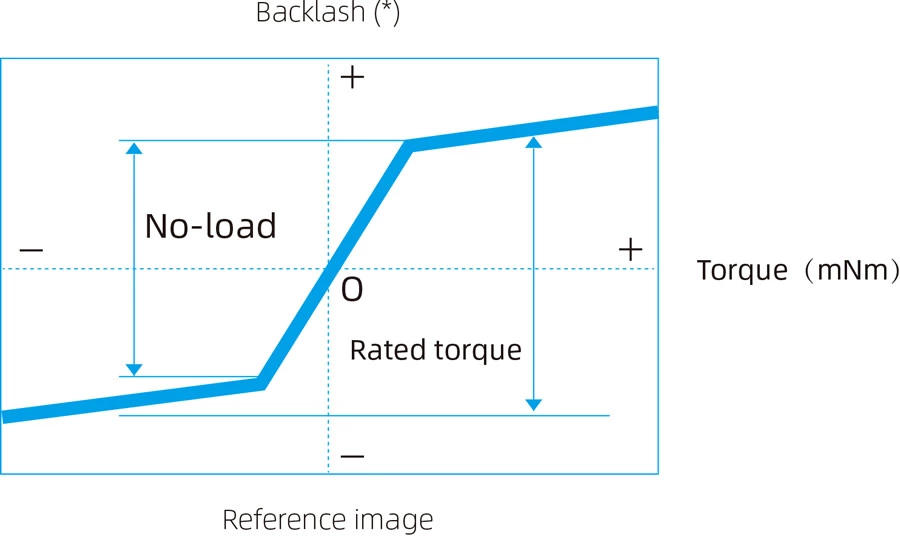

Backlash

The amount of gearheads backlash depends on a play required for smooth meshing and a play between the shaft and the bearing. Note, however, it increases under load due to elastic deformation.

Tell Us About Your Application Requirements

ZHAOWEI team welcomes your arrival,By understanding your needs in advance, we will prepare corresponding solutions to facilitate on-site coordination and quickly address your concerns. We look forward to communicating and collaborating with you!

Customer Service

ZHAOWEI’s micro drive systems apply in diverse areas all around the world to deliver the power, precision, and efficiency to motion solutions. Our sales and engineering support teams are ready to assist you with any questions, including quotation, application support, and product configuration. Please submit your requirements through our Custom Service Form to ensure a faster response.

This website uses cookies

This website uses anonymous performance cookies to ensure you get the best experience on our website. We never use targeting or advertising cookies. Find out more: Cookies Policy