The gearbox design platform of ZHAOWEI ’ s independent intellectual property rights realizes the automatic parameter design of involute gear structures and solve the technological problems of the efficiency, noise and service life of gearboxes.

Solution Design

Structure Design

Gear Tooth design

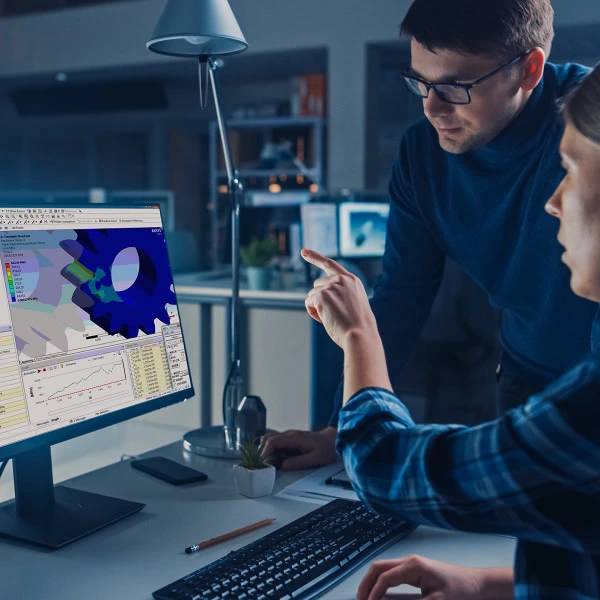

Simulation Analysis

Performing dynamic simulation and strength check on the transmission system, shortening products development cycles and redesign times and designing more reasonable products that meet customer requirements.

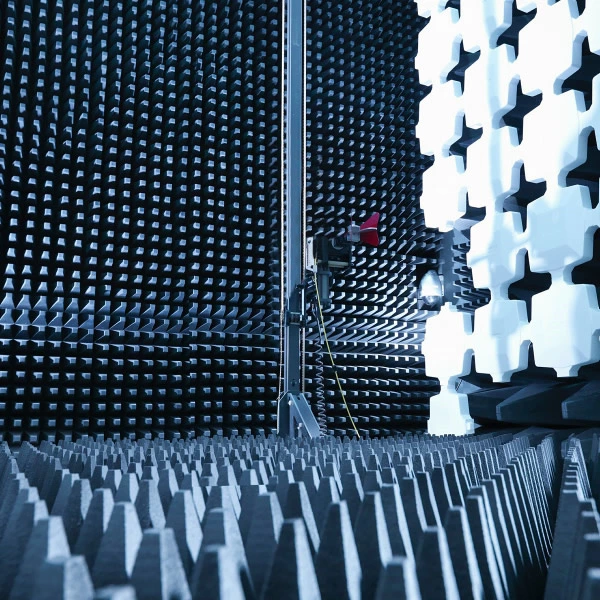

Adopting Danish B&K acoustic analysis system for acoustic vibration experiment analysis.

Committed to micro drive and motor control module development

Modular software development enables online debugging of parameters

Small and integrated design that meets automotive standards

Well-established test standards based on national standards

Committed to the development and production of precision drive systems and providing customers with intelligent drive solutions and customized services for the production and assembly of precision parts.

Customized SolutionsThis website uses anonymous performance cookies to ensure you get the best experience on our website. We never use targeting or advertising cookies. Find out more: Cookies Policy