Racing at the future track,Exploring concept car

Starting , a conversation with the future

Brushless DC motors are used according to customer requirements.

Motor parameter for reference

No-load Speed: 3000-6000RPM

Rated Voltage: 12V

No-load Current: 0.1-0.7A

Outer diameter: 31-51mm

The above parameters can be customized.

Gearbox parameter for reference

Working Noise Range: ≤60dB

Load Speed Range: 2RPM-5.2RPM

Load Torque Range: 0.5N.M-7N.M

The above parameters can be customized.

1. Achieving low power consumption with a quiescent current of less than 0.2mA at 13.8V

2. Adopting “BLDC+FOC” control to realize high load and low noise.

3. Using CANFD to connect with the car and achieve the function of instructing, diagnosing, and AutoSar network management.

4. Hover at any angle with anti-catch function.

1. Two in-place detection switches are added to the lock bolt to realize the judgment in different states of midway blocking and in-place blocking.

2. The product adopts the structure of double worm gear and distributed structure of power end and encoder detection end, which has the advantage of compact size, strong load performance, and high space utilization.

3. The damper and the input power end are designed at the same side, which achieves coaxial installation of the product and the screen backshell, as well as realizes the screen hovering at any angle.

With the design of “DC brushless motor + worm gear + parallel transmission”, ZHAOWEI’s drive system enables the automotive display to rotate up to 90°and tilt up to 15°, which realizes screen perspective switching and comfortable driving.

ZHAOWEI’s roof monitor drive system adopts the design of worm gear with motor, using the propulsive force of the push rod and the gravity of the display to realize the opening and closing of the roof monitor and reduce the vibration noise caused by the poor concentricity of the transmission device. The product can work up to 20000 times and angular deviation within 0.5°

The product is composed of DC brushless motor, lift coupling, gearbox, PCBA, and connection bracket, which realizes the automotive display lifting by linear actuator motion. Through single head worm gear self-locking structure and mechanical limit, the gap between gears can be eliminated.

The automotive display camera drive system is similar to the phone pop-up camera, which adopts the design of stepper motor with gearbox. The lifting module is driven by a stepper motor to move the metal module up and down, which enables the camera to lift stably with low noise.

ZHAOWEI has Smart Control Laboratory, Transmission System Laboratory, and Gear Testing Laboratory, controlling products quality from transmission design, tooth design, strength check, CAE simulation, noise analysis, and other dimensions.

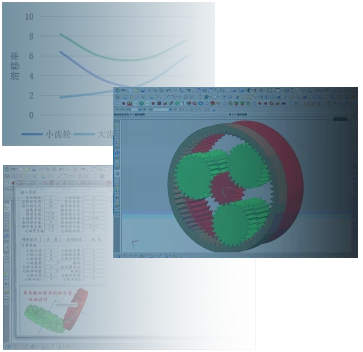

The self-developed micro drive design software covers a variety of transmission forms of rapid precision modeling greatly improving the development efficiency.

Modification coefficients selection

All-in-one parameter design

Efficiently and precisely molding

Designing gear tooth profile by ZHAOWEI self-developed software to achieve details design such as gear parameters design and micro-geometrical design.

Shaping gears and doing parametric design through ZHAOWEI's strong database.

Gear tooth profile

design software

Parametric tooth design

for mold cavities

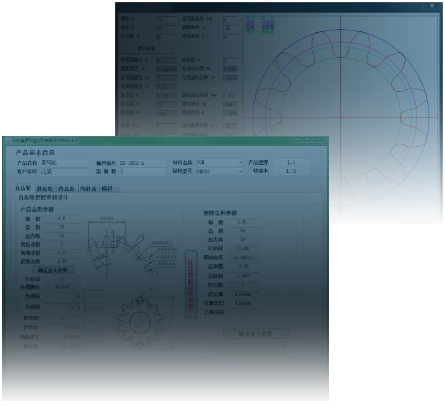

Checking bending fatigue strength gears of different materials under different working conditions based on the gear transmission software to analyze and optimize gear tooth contact stresses.

Gear strength check

Gear tooth contact analysis

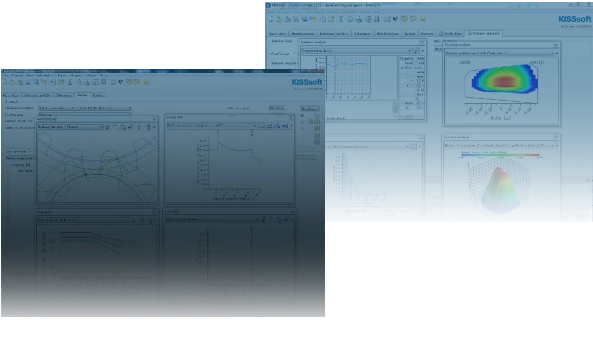

Mechanical simulation analysis of the transmission system based on customer requirements.

Drop simulation of the miniature

transmission system

Gearbox shell modal simulation

Influence of tooth root filtration curve

on tooth root bending strength

Simulation of transient contact force of

helical gear pair under different side gap

Influence of tooth top fillet angle on

contact stress during the reverse drive

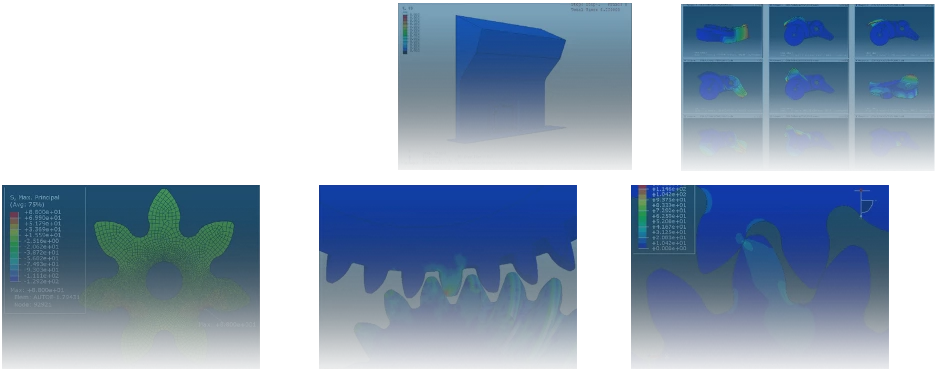

Sound vibration analysis with Danish B&K acoustic analysis system

Paulse - experimental modal analysis

Connect - gearbox waterfall diagram analysis

Gearbox noise spectrum analysis