50mm Drum Motor Series

Model: ZW50Series

·High efficiency ·High load capacity ·High stability guarantee

·Low noise ·Low power ·Low failure rate

- Diameter

- 50mm

- Voltage Range

- 24V/48VDC, Customizable AC

- Load Speed

- 64-1380 rpm

- Reduction Ratio

- 5-108

- Power

- 35-80W

- Constant torque

- 0.6-12.38Nm

- Rated Line Speed

- 0.17-3.61m/s

- Roung Belt

- Optional

- Playload

- 30-360(μ=0.05)KG

- Operating Temperature

- -40…+55℃

Application:For box conveyor lines such as cartons, bins, platens or tires. Suitable for linear conveyors, small belt conveyors, especially zero pressure

accumulation conveyors.Also for shuttle systems, mating conveyor sections or transplanters with other conveyors.

Gearbox Specifications:

| Gear Ratios | 5 / 7 / 13 / 18 / 25 / 30 / 42 / 65 / 78 / 90 / 108 | |||||

| Gearbox Material | R: Powder metallurgy, IP54 S: Ground gear, IP54 Q: Powder metallurgy, IP66 T: Ground gear, IP66 A: Plastic gear, IP54 B: Plastic gear, IP66 |

|||||

Basic Parameter:

| Rated Voltage | 24V | 48V | ||||

| Rated Current (A) | 2.2 | 3.1 | 4.5 | 1.1 | 1.5 | 2.3 |

| Start-up Current (A) | 5.5 | 7.8 | 11.3 | 2.8 | 3.8 | 5.8 |

| Rated Power (W) | 35 | 50 | 80 | 35 | 50 | 80 |

| Maximum Noise | 50db | |||||

| Cable Length | Hall Power Roller: 1m (extendable by 1m) Magnetic Encoder Power Roller: 0.5m standard (extendable by 2m) |

|||||

| Protection Class | IP54/IP66 | |||||

| Tube Material | Galvanized Steel, Stainless Steel | |||||

| Tube Size | φ50x1.5mm | |||||

| Shafts | M12 male thread hex , Hex 11 , Double D | |||||

| Operating Temperature | -40℃ ~ 55℃ | |||||

| Drive Mode: | Z: Direct drive; P: Poly-V pulley; O: O-type pulley; N: Timing pulley; L: Double-strand sprocket; M: Cam; X: Non-standard Optional materials: 1: Plastic; 2: Carbon steel, galvanized; 3: Carbon steel, blackened; 4: Stainless steel; 5: Aluminum alloy; 6: Powder metallurgy; 7: Carbon steel, chrome plated |

|||||

| Drive Power Configurations | C: Magnetic encoder, D: Hall 1:35 W, 2:50 W, 3:80 W, 8:120 W |

|||||

| Cable outlet configurations | T1: With M12×1 threaded HEX; T2: HEX11 without thread; T3: Double-D; T4: Dual-bearing hexagonal shaft (stainless steel); TX: Non-standard |

|||||

| Non-cable end mounting options | H: Carbon steel, galvanized; K: Stainless steel; M: Carbon steel, blackened 1: Spring-loaded press-fit HEX11; 2: Fixed hexagonal shaft; 3: M8 internal thread; 6: Double-D |

|||||

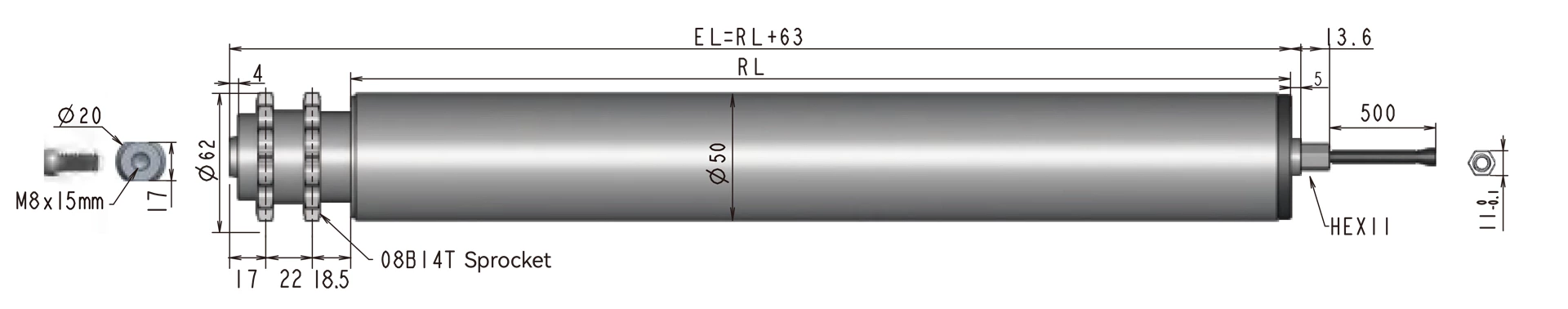

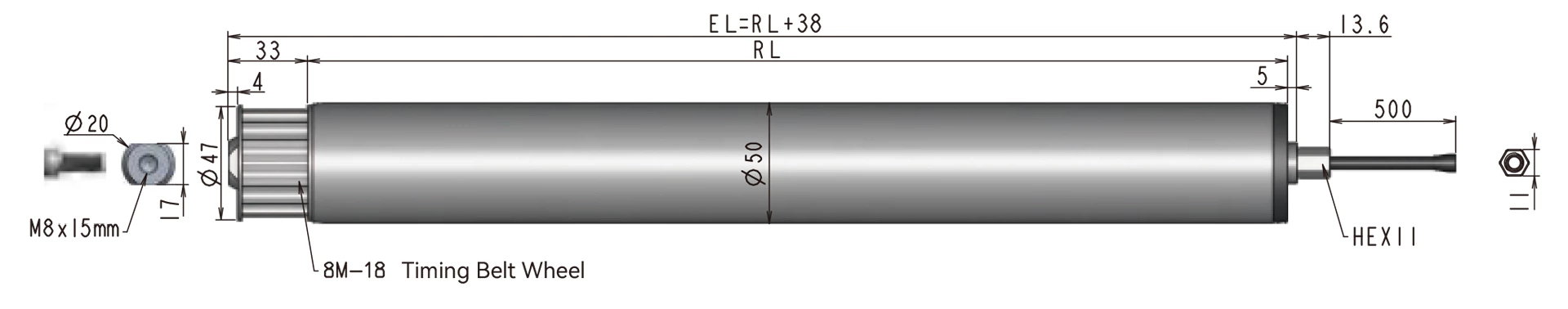

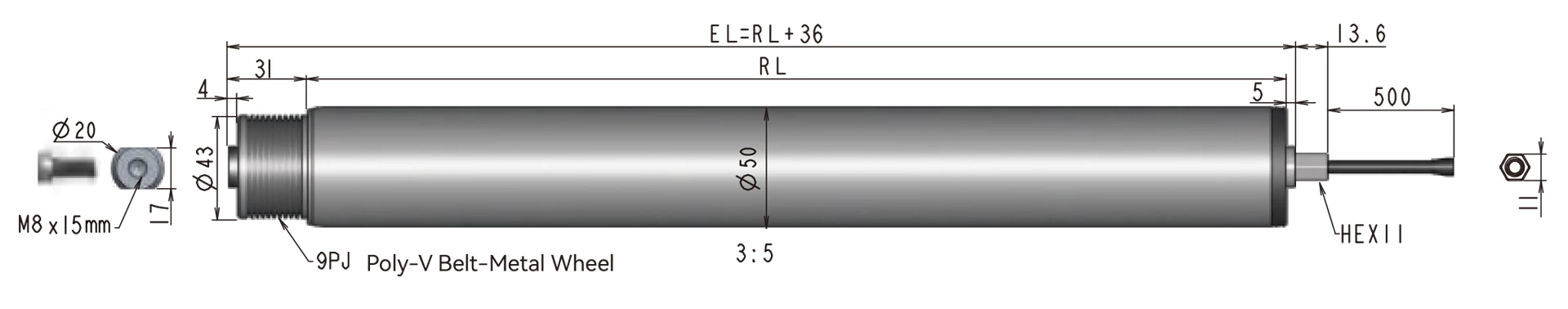

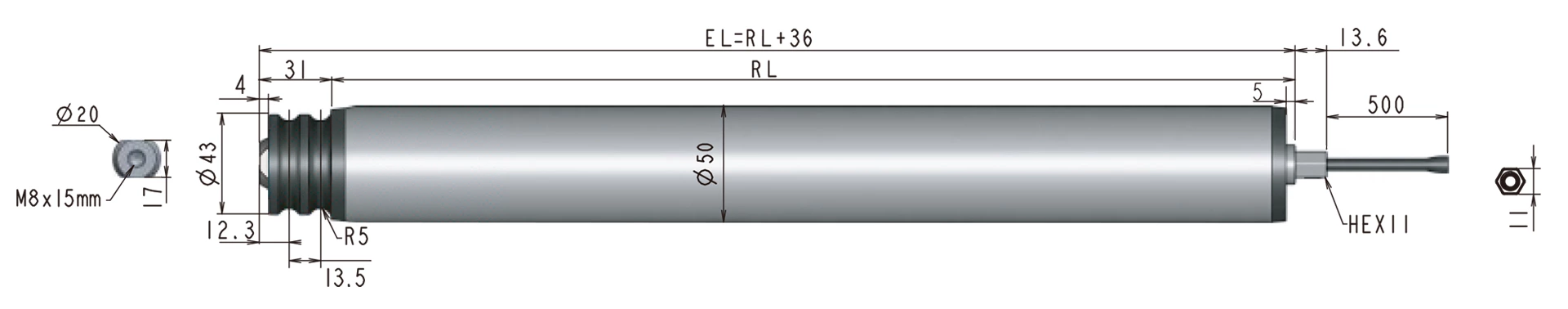

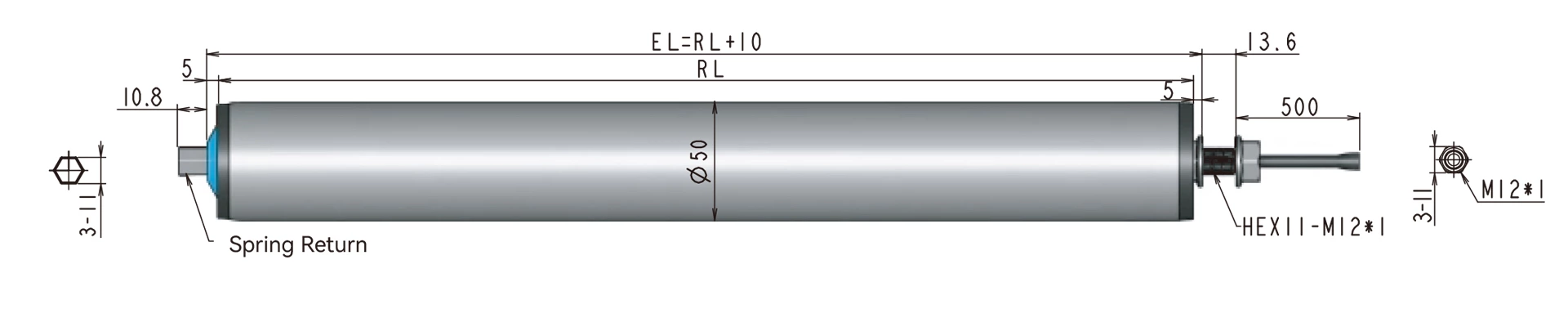

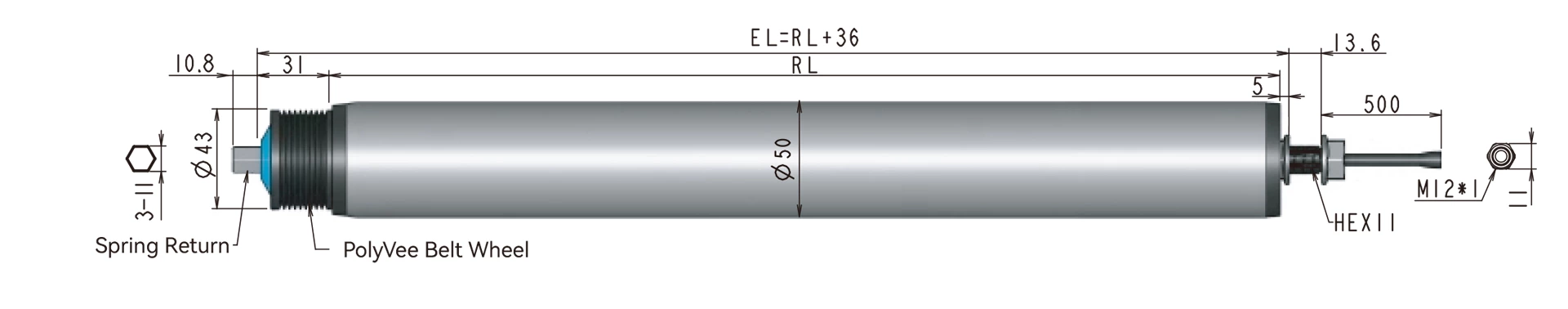

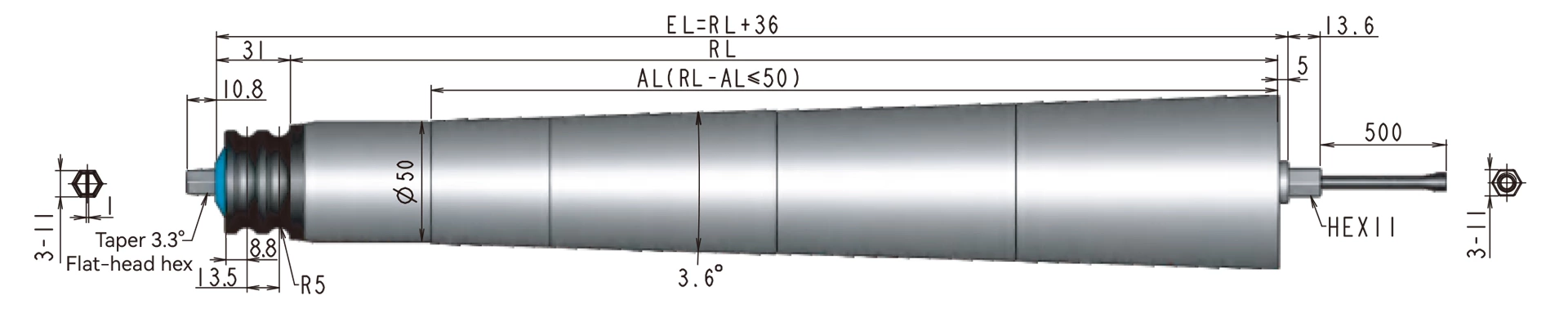

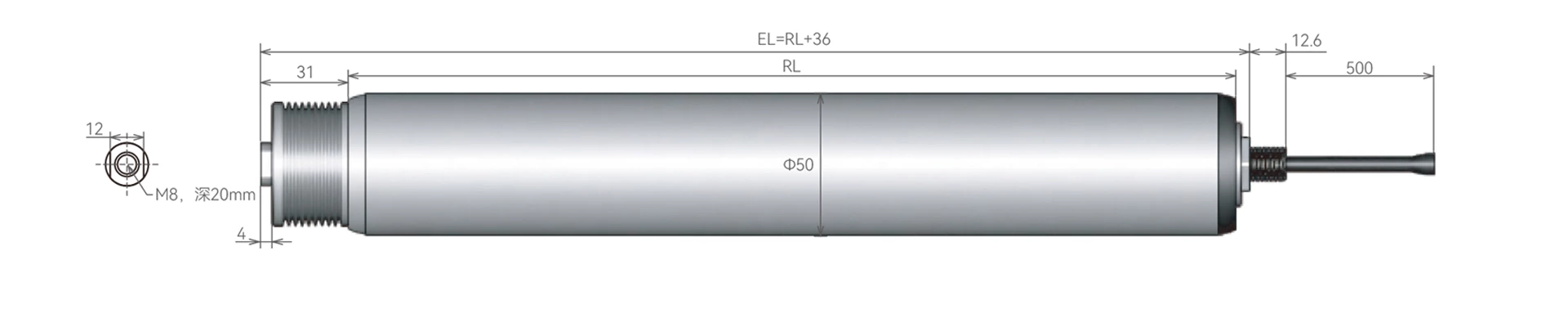

Drawing:

L: Sprocket

N: Timing Belt

M: Poly-V Belt Drive-Metal Wheel

O:Roung Belt

Z: Direct-Drive Hex11

P: PolyVee Belt

Tapered:

IP66:

Performance Data:

| 80W | 50W | 30W | ||||||||||

| Speed Code | Ratio | Rated Output (rpm) |

Rated Line Speed (m/s) |

Rated Turque (N.m) |

Start-up Torque(N.m) | Playload* (μ=0.05)KG |

Rated Turque (N.m) |

Start-up Torque(N.m) | Playload* (μ=0.05)KG |

Rated Turque (N.m) |

Start-up Torque(N.m) | Playload* (μ=0.05)KG |

| S1 | 5 | 1380 | 3.61 | 0.6 | 1.49 | 30 | 0.36 | 0.9 | 20 | 0.26 | 0.65 | 10 |

| S2 | 7 | 986 | 2.58 | 0.84 | 2.09 | 40 | 0.49 | 1.23 | 30 | 0.34 | 0.85 | 15 |

| S3 | 13 | 531 | 1.39 | 1.55 | 3.88 | 75 | 0.91 | 2.28 | 50 | 0.64 | 1.6 | 35 |

| S4 | 18 | 383 | 1 | 2.1 | 5.24 | 100 | 1.27 | 3.18 | 70 | 0.89 | 2.23 | 50 |

| S5 | 25 | 276 | 0.72 | 2.91 | 7.28 | 140 | 1.76 | 4.4 | 100 | 1.24 | 3.1 | 70 |

| S6 | 30 | 230 | 0.6 | 3.49 | 8.73 | 170 | 2.13 | 5.33 | 115 | 1.49 | 3.73 | 80 |

| S7 | 42 | 164 | 0.43 | 4.89 | 12.22 | 240 | 2.96 | 7.4 | 160 | 2.07 | 5.18 | 110 |

| S8 | 65 | 106 | 0.28 | 7.35 | 14.71 | 360 | 4.58 | 11.45 | 250 | 2.95 | 7.38 | 160 |

| S9 | 78 | 88 | 0.23 | 8.85 | 17.7 | 360 | 5.07 | 12.68 | 275 | 3.55 | 8.88 | 200 |

| S10 | 90 | 77 | 0.2 | 10.21 | 18 | 360 | 5.89 | 14.73 | 320 | 4.1 | 10.25 | 220 |

| S11 | 108 | 64 | 0.17 | 12.26 | 18 | 360 | 7.07 | 17.68 | 360 | 4.95 | 12.38 | 270 |

Tapered Reference Dimensions:

| Length | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 |

| Min. Dia. | 52.5 | 55.6 | 52.5 | 55.6 | 52.5 | 55.6 | 52.5 | 55.6 | 52.5 | 55.6 | 52.5 | 55.6 | 52.5 | 55.6 | 52.5 |

| Max. Dia. | 71.2 | 77.6 | 77.6 | 84 | 84 | 90.4 | 90.4 | 96.8 | 96.8 | 103.2 | 103.2 | 109.9 | 109.9 | 116 | 116 |

*The drive loads are reference values, the exact values need to be calculated in conjunction with the actual application.