Low-Speed Handpiece Motor Parameters

Dental handpieces can be divided into high-speed and low-speed according to speed and structure. High-speed handpieces use high-pressured air to drive the micro-turbine on the handpiece head. The turbine speed can reach up to (3-5) × 10r/min, and cutting speed of the dental bars can reach 15m/s. The speed of low-speed handpieces can be regulated by the speed regulating structure. A dental low-speed motor is a gear drive module used in dental equipment and instruments, also known as a dental gear motor. Its main transmission structure is assembled by a drive motor (micro motor) and a planetary gearhead (reducer). The drive motor uses a micro motor, DC motor, stepper motor or coreless motor as the drive source, while the micro gearbox can use a planetary gearhead, common gearhead, or worm gearhead as the reducer. The technical parameters of low-speed handpiece motors are often customized for development, including the output power, voltage, current, specification, dental handpiece gear ratio, output torque, transmission precision, and transmission noise.

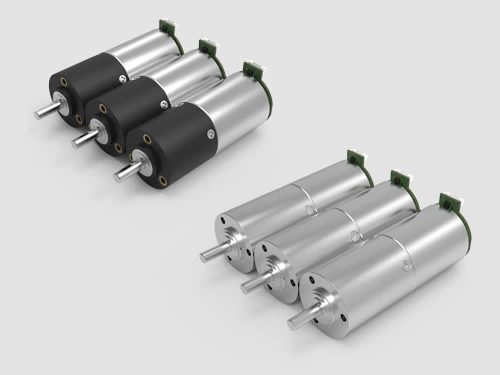

ZHAOWEI Machinery & Electronics Co., Ltd provides a set of customized development service. The customized technical parameters of low speed handpiece motors with gearboxes provided by ZHAOWEI are shown below:

Diameter: 3.4mm-38 mm

Voltage: ﹤24V

Output power: ﹤50W

Output speed: 5-2000rpm

Reduction ratio: 5-1500

Output torque: 1.0 gf.cm -50kgf.cm

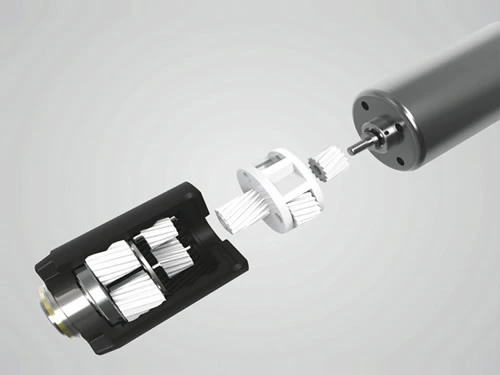

Project Name: Precision Planetary Gearheads for Dental Handpieces

Project Difficulties: During oral treatment, the patients’ saliva, blood, and spit are adsorbed into the dental handpieces. It is challenging to clean complex turbine bearings, water inside the instrument, gas pipes, and gaps, this increases the risk of cross-infection.

Achievement: ZHAOWEI has developed an automatic damping reduction gearbox, which uses a turbine worm structure and a planetary gearhead to achieve a compact size, high torque and low-noise. The entire gear and gear profile have been modified to greatly reduce the noise and the vibration impact on the performance of this module.

Characteristics:

1. It uses the design concept and scheme of the planetary gear industry - the noise and vibration can reduce significantly as long as the precision difference is within 1 micron. The function of noise reduction can improved low-noise in handpieces when conducting oral treatment.

2. The combination of the worm gear structure and planetary gearheads makes high torque possible. This reduces the risk of surface contamination caused by contact with the saliva, blood, and spit of patients, on the handpieces, during operation, and internal contamination of handpieces caused by the penetration of saliva and blood via the gap of the handpiece itself.