Product Parameters and Applications of Micro Electric Telescopic Motor

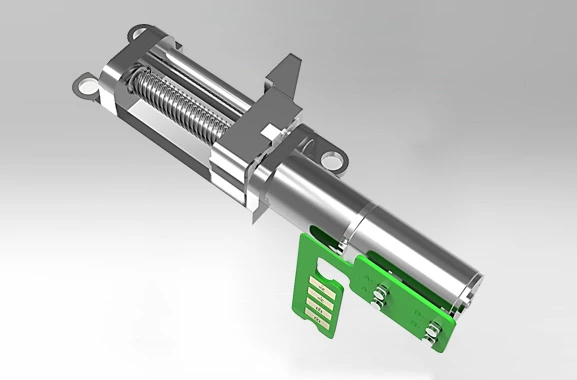

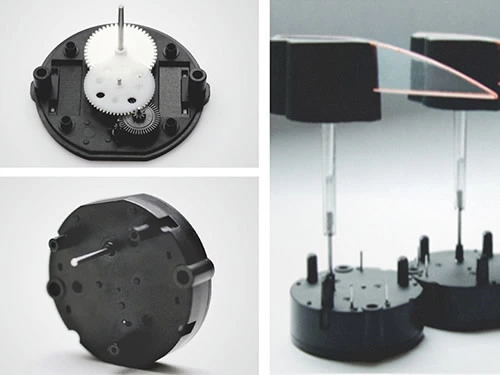

The micro linear actuator is an electric drive device that converts the rotational motion of the motor into the linear reciprocating motion of the pushrod. It can be used as an actuator in various simple, or complex technological processes to achieve remote, centralized, or automatic control. After gear or worm deceleration, the motor drives a pair of screw nuts. The rotary motion of the motor is changed into a linear motion, and the push-rod action is completed with the help of positive and negative rotation. The micro electric telescopic motor is a small drive motor with an automatic telescopic function. Its main transmission structure is assembled by a driving motor, telescopic pushrod (screw), and a planetary gearhead. The drive motor can utilize a DC motor, BLDC motor, brush motor, stepper motor, or coreless motor as the driving source. The micro gearbox can utilize a planetary gearhead, cylindrical gearhead, worm gearhead, or parallel-shaft planetary as the reducer. The pushrod (screw) can be customized for development according to requirements. The technical parameters of micro electric telescopic are often customized for the development of different applications, including the output power, gear ratio, voltage, torque, type of driving motor, the structure of gearbox, noise, and transmission precision.

ZHAOWEI Machinery & Electronics Co., Ltd provides customization and development services. The customized technical parameters of micro electric telescopic motors provided by ZHAOWEI are as follow:

Diameter: 3.4mm-38 mm

Voltage: ﹤24V

Output power: ﹤50W

Output speed: 5-1500rpm

Gear ratio: 2-2000

Output torque: 1.0 gf.cm -50kgf.cm

Parameters of Micro Electric Telescopic Motor:

| Material | Metal |

|---|---|

| Outer diameter | 6mm |

| Operating temperature | -20℃~+85℃ |

| Direction of rotation | cw&ccw |

| Gear backlash | ≤3° |

| Voltage (Optional) | 3V~12V |

| Bearing | Porous bearing/Rolling bearing |

| Input speed | ≤30000rpm |

| Axial endplay | ≤0.3mm/≤0.2mm |

| Current | 250mA max |

| Radial load on output shaft | ≤0.5N/≤5N |

| Motors (Optional) | Stepper/Brushed DC/BLDC Motor |

Customization and Application of Micro Electric Telescopic Motor:

Micro Electric Telescopic Gear Motor Used in Full-Screen Phone with Pop-up Cameras

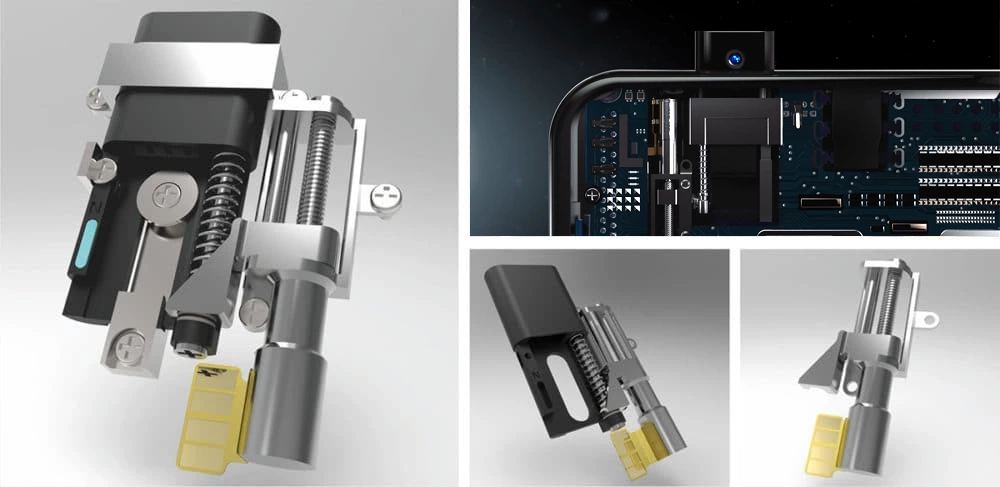

Project Name: Gear Motor for Full-Screen Phone Camera

Project Description: 5G technology and full-screen interaction have caused much confusion on front camera placements. ZHAOWEI has developed a gear motor (3.4mm, 4mm, and 5mm) transmission system, which can help create the rotation and lifting of full-screen mobile phone cameras. This allows cameras to rotate frontwards, backwards, and at other angles, and for the camera to pop up. This makes for the ideal placement of a full-screen phone front camera.

Micro Electric Telescopic Gear Motor Used in the Auto Lifting Camera of Smart TV

Project Name: Camera Gear Motor

Project Description: The ZHAOWEI camera gear motor includes a lifting drive system, with both coaxial and parallel-shaft screws, and a rotating system formed by planetary gearheads and gears (circular motion). The planetary gearheads, stepper motor, fixed bracket, and drive screw form a camera lifting system to drive the lifting movement of the camera. This is suitable for pop-up cameras on full-screen mobile phones, laptops, and TVs. Planetary gearheads, parallel-shaft gear, stepper motor, fixed bracket, and rotation axis come together to drive the rotation of the camera, suitable for the front rotation of both phone and laptop cameras.