How to Select a 25mm Gear Motor?

From heavy-duty AC motors, to tiny DC motors, there are a variety of choices in motors on the market today. In order to select the right motor, users are required to have a full understanding of the application parameters. This includes power, speed, torque, physical size, efficiency, and lifetime expectations. It would be difficult to describe them all accurately in a short article. Instead, we will show you how to select a 25mm gear motor from some relatively important aspects.

Selection Criteria: Measure Basic Parameters

- Applications: Confirm the usage and application scenarios of the 25mm DC gear motor, and list factors such as environmental requirements under the application before purchasing.

- Determine speed. An important measurement to consider is revolutions per minute (RPM), which describes the speed of the motor. The speed of the motor is proportional to the power supply voltage, and inversely proportional to the armature voltage drop. Based on field findings, it is also inversely proportional to the flux. The selection principle of gear motors is as close to the rotational speed of the production machinery as possible to simplify the rotating device.

- Determine the reduction ratio. The reduction ratio, or transmission ratio, refers to the ratio of the instantaneous input speed to the output speed of the reduction mechanism, represented by the symbol “i”. For example, if the input speed of a 25mm motor is 1500r/min, and the output speed is 25r/min, the reduction ratio is i=60:1. The calculation formula is Reduction Ratio = Motor Output Revolution ÷ Gear Reducer Output Revolution.

- Determine the required motor torque. Motor torque, one of the basic parameters of the motor, is the output torque of the motor. The measuring unit is N.M (Newton. Meter). One of the calculation formulas is: T=9550*P/n. T–Torque; 9550–constant (no need to investigate its source); P–the power of the motor (KW); n–output speed (rev/min). It should be noted that if you use this formula to calculate the torque, you must consider the loss of gear transmission efficiency.

- Power selection. The power selection of gear motor is determined by the production machinery, that is, by the power required by the load. The motor power required for the gear motor is: Motor Power = Torque ÷ 9550 × Motor Power Input Speed ÷ Speed Ratio ÷ Use Coefficient. For the use coefficient, the formula is: Use Coefficient = Rated Output Power/Motor Power (to get the use coefficient of the gear motor type with continuous load).

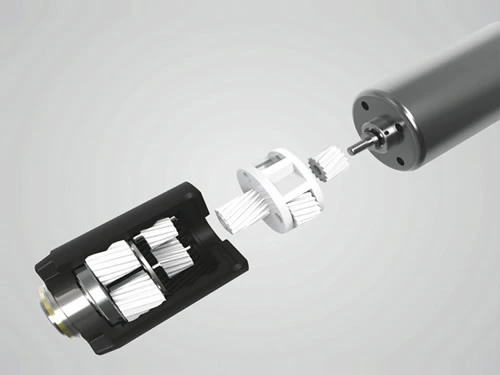

- Pay attention to the gear backlash. Gear backlash accuracy directly affects work efficiency and service life. The ZHAOWEI drive system consists of a powerful motor adapted to the urgently required miniaturization trend, and a high-precision planetary gearbox with a backlash less than 1 arc minute. The gear backlash is controlled to achieve the standard within a small arc, thereby reducing the noise of the product.

- Material requirements. The gear materials of 25mm gear motors often include metal and plastic. Most people assume that metal gears are significantly better than plastic gears. Plastic gears are considered fragile and likely to break at any moment. However, they both have their own advantages and disadvantages. Which material you choose depends on your application.

Product Recommendation

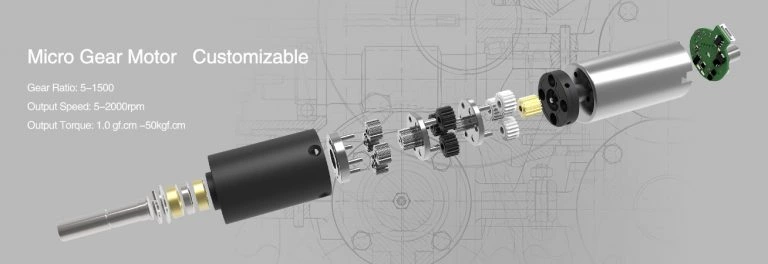

ZHAOWEI provides customized services for the development of different technical parameters, such as diameter, output speed, output power, rated voltage, the output gear ratio, and output torque. To determine the size of a DC motor to a specific application, first match the diameter of the motor with the available space. The diameter of ZHAOWEI’s customized service ranges from 3.4mm to 38mm. A 25mm gear motor is also included. In terms of standard drive systems, there is no 25mm DC gear motor in the ZHAOWEI product list. We’ve taken the 24mm standard drive system here as an example.

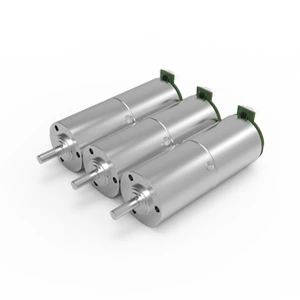

Product 1: 24MM 12V Plastic Gear Motor

Model: ZWBPD024024-XXX

- Rated Voltage: 12V

- No-load Speed: 5-1,460 rpm

- No-load Current: 70-80 mA

- Rated Load Speed: 4-1,259 rpm

- Rated Load Current: 215-220 mA

Product 2: 24MM 12V Metal Gear Motor

Model: ZWBMD024024-XXX

- Rated Voltage: 12V

- No-load Speed: 5-1,460 rpm

- No-load Current: 70-80 mA

- Rated Load Speed: 4-1,259 rpm

- Rated Load Current: 215-220 mA

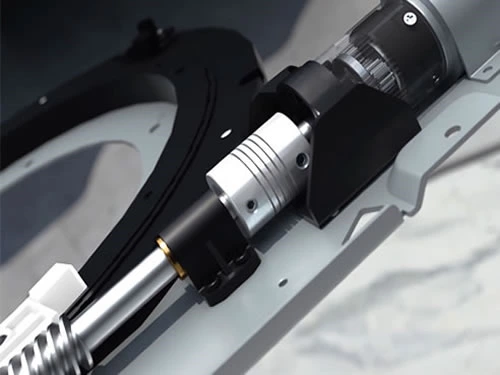

The both use a combination of planetary gearheads and micro motors. Great performance contributes to a wide range of applications, from automobile, 5G communication, smart medical, smart homes, consumer electronics, intelligent robots, to industrial automation.

We offer many different styles and sizes of Gear Motors, so you can find the right combination of torque, speed and size for your application. Use filters to narrow the range of results by setting known parameters to find a motor that better meets your needs. For more information regarding 25mm DC gear motors, please contact a qualified ZHAOWEI engineer.