Types of Gear Reducers and Their Characteristics

Gear reducers are widely used reduction transmission equipment. The main transmission structure integrates the drive motor (motor) and gearbox (reducer). It is also called a gear motor. The drive motor can use a DC motor, brushed motor, brushless motor, stepper motor, coreless motor, servo motor, etc. The gearbox reducer can use a planetary gearbox, cylindrical gearbox, parallel-shaft gearbox, worm gearbox, or screw gear. When categorizing drive motors by type, they can be divided into DC gear motors, stepper gear motors, brushed gear motors, brushless gear motors, coreless gear motors, etc. Based on structural types of gearboxes, reducers can be divided into planetary gear motors, gear reducers, worm gear reducers, parallel gear reducers, screw gear reducers, etc. Different types of gear reducer motors have different uses.

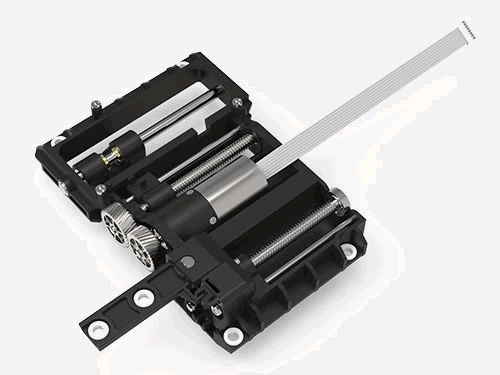

Gear Reducer

The gear reducer uses multi-gear transmission to achieve speed reduction. It is composed of various gear trains. For example, a small gear can be used to drive a large gear to achieve a specific reduction. With a multi-stage gear structure, the speed can be greatly reduced. The gear reducer is space-saving, reliable, and durable, and has a high overload capacity, low energy consumption, low vibration, low noise, and good performance. And the reducer efficiency is up to 95%. It uses high-quality forged steel, a rigid cast-iron box body, and high-frequency heat treatment on the surface of the gear. Finish machining is used to meet shaft parallelism and position bearing requirements. The reducer forming the helical gear transmission assembly is equipped with various types of motors, combined into mechatronics.

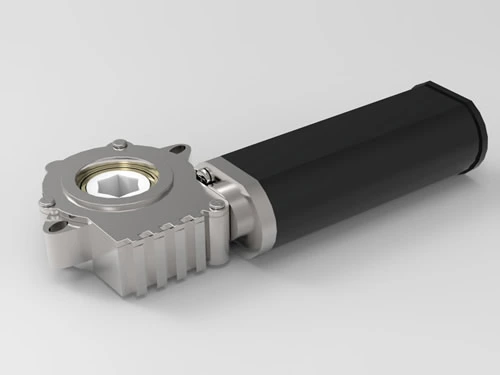

Planetary Gear Reducer

The planetary reducer is an industrial product that is also a transmission mechanism. It normally consists of a motor and planetary gear (made up of a sun gear, planet gears, and a ring gear.). The planet gear relies on the support of the output shaft, the inner gear ring, and the sun gear. When the input power drives the sun gear, the planetary gear can be driven to rotate and revolve along the center following the trajectory of the inner gear ring. The rotation of the planet gears drives the output shaft connected to the tray to output power. The planetary reducer has the characteristics of a small size, light weight, high carrying capacity, long service life, stable operation, low noise, high output torque, large speed ratio, high efficiency, and safe performance. It features power splitting and multi-tooth meshing and is a new type of reducer with wide versatility.

DC Reducer

The DC reducer motor, or DC gear motor, is an ordinary DC motor combined with a gearbox. The function of the gearbox is to provide a lower speed and higher torque. The DC geared motor saves space, and is reliable, can withstand a certain overload capacity, and can meet the power requirements; the DC geared motor has low energy consumption, great performance, small oscillation, low noise, and saves a lot of energy. It is made with high-quality forged steel and rigid cast iron. The body and gear surface are heated up and the new type of sealing device has good protection performance and strong adaptability to the environment, which enables the DC gear motor to work continuously in harsh environments when facing corrosion and humidity.

Worm Gear Reducer

The worm gear reducer is a power transmission mechanism that uses the gear to reduce the number of revolutions of the motor to the required number and obtain a higher torque. The worm gear reducer has a compact mechanical structure, light volume, high efficiency, good heat exchange performance, fast heat dissipation, and is easy to install. It’s flexible and light, performs well, and easy to maintain and repair. It has stable operation, low noise, high durability, strong usability, high safety and reliability.