Why Choose a Gear Drive System?

Mechanical drives can be divided into two categories. One is friction transmission, which transmits power and motion by friction between parts, including the belt drive, rope drive, and friction wheel drive. Generally, this type of drive is not used in high-power situations because it does not provide accurate gear ratios.

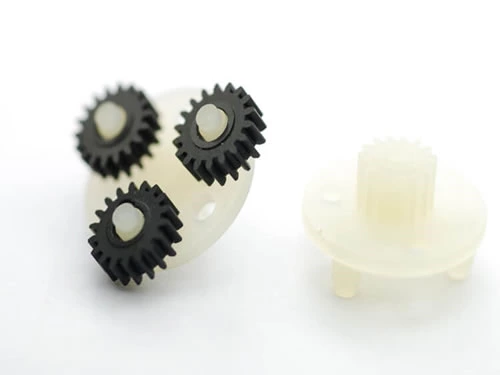

The second is the meshing transmission, which transmits power or motion by engaging the driven unit with the driven unit or the middle member, including gear transmission, chain transmission, screw transmission, and harmonic transmission. The gear drive relies on two or more intermeshing gears to transmit power. The gear transmission ratio is accurate, which is suitable for high manufacturing precision and installation accuracy.

Advantages of Gear Drive System:

1) Instantaneous transmission ratio is constant and operation is stable.

2) Using non-circular gears, the instantaneous transmission ratio can be designed according to the required rule of change.

3) The gear ratio has a wide range of variations, which is suitable for deceleration or acceleration transmission. A large gear ratio can be achieved, especially when a planetary drive is used.

4) Peripheral gear speed can reach a higher level.

5) The transmission power range is wide and the carrying capacity is high.

6) High transmission efficiency, especially for cylindrical gear pairs with high precision.

7) By using planetary transmission, less-tooth-difference transmission, or harmonic gear transmission, the components can be further reduced, enabling coaxial transmission and keeping the structure compact. Planetary transmission is suitable for high-precision drives. The diameter range of ZHAOWEI planetary gearboxes starts from 3.4 to 38mm.

8) Easy maintenance and uniform load distribution.

Disadvantages of Gear Drive System:

1) High precision in manufacturing and installation is required.

2) The manufacturing process is complicated and costly.

3) Not suitable for transmission between two axes at a long distance.