DC Gear Motor with Rated RPM

What is the RPM of a DC Gear Motor?

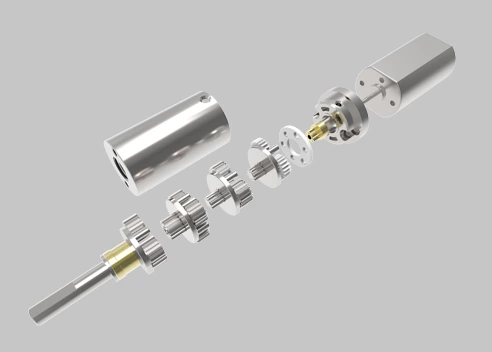

RPM, a measurement used to describe a DC gear motor’s speed, stands for revolutions per minute. It describes the rate at which the rotor is revolving, i.e., the number of times the rotor shaft completes a full rotation each minute. In DC gear motors with gear assemblies attached, speed can be decreased and torque can be increased for applications that require different speeds.

Why is it Important to Calculate RPM?

When selecting a motor for a given application, calculating motor RPM, and other measurements (such as torque, voltage, and power), are essential. Calculating motor speed allows you to choose the correct motor type when replacing components, and helps you make better repair decisions. A better understanding of RPM also helps to effectively control and monitor motor operations. The micro DC motor is a type of rotating motor driven by direct current (DC) electrical energy. In order to reduce speed for expected torque, the DC motor can sometimes add and customize the controller or gearbox according to various application requirements.

ZHAOWEI DC motors are easy to install, have high efficiency, easy RPM management, low-noise, high starting torque, and long service life. They can be customized according to various application requirements. For the ideal speed that you’re after, ZHAOWEI provides a variety of micro DC motors, which can offer the required rated RPM. The following are 4 typical cases of DC gear motors with different rated RPM. Intelligent drive system

Typical Cases of DC Gear Motor with Rated RPM:

1) 30 RPM DC Gear Motor:

Model: ZWPD008008-249

Product Name: 8MM 30 RPM DC Gear Motor

Introduction: ZWPD008008-249 is one of the models with an 8mm plastic planetary gearbox and a rated speed of 30 RPM. The ZHAOWEI 30 RPM DC gear motor utilizes the combination of plastic planetary gearheads and motors. The nut is easily connected to threads on the shaft, and the internally threaded shaft is easily connected to the wheel. Robot applications usually use 30 RPM DC geared motors because its easy application achieves the expected speed.

2) 6V 50 RPM Geared DC Motor

Model: ZWBPD028028-144

Product Name: 28MM 6V 50 RPM Geared DC Motor

Introduction: The 28mm diameter ZHAOWEI 50 RPM geared DC motor adds a plastic planetary gearhead on the motor to make it whole. The driving motor can be a coreless motor, brushless motor, or a stepper motor. ZHAOWEI provides a flexible voltage range for custom development, and 6V is no exception. Those who need a rated speed of 50 RPM can choose this 28mm plastic planetary gearbox.

3) 200 RPM DC Gear Motor:

Model: ZWMD012012-36

Product Name: 12MM 200 RPM DC Gear Motor

Introduction: ZWMD012012-36 makes it possible to reach approx. 200 RPM, resulting in high torque and low RPM performance. More precisely, it can reach 208 RPM. It consists of a metal planetary gearhead with a 12mm diameter, which is very popular. High-temperature resistance, high wear resistance, and strong loading capacity effectively protect the gear motor body. Therefore, long service life is one of its main highlights.

4) 300 RPM Gear Motor:

Model: ZWMD038038-25

Product Name: 38MM 300 RPM Gear Motor

Introduction: ZWMD038038-25 belongs to the 300 RPM gear motor series. The use of precision technology improves the quality of the bearing, and the service life of the gear motor, enhancing durability. Even in a compact space, the high torque and low RPM it generates can still help achieve ideal operation performance at low-noise.

The gear motors provided by ZHAOWEI Drive better meets the expected RPM required by each application. The aforementioned cases are only part of the standard DC motor models. Whether it’s 30 RPM DC gear motors or 300 RPM gear motors, they have the following common features:

- 1.Metal & Plastic Planetary Gearheads Available. Its special structure gives the precision gear motor the ability to reduce speed and increase torque.

- Great Customization. It is feasible to customize suitable gear motors with expected parameters (such as torque, backlash, shaft, bearings, and operating temperature) for your own application.

- Compact. Multiple diameters are available for the gear motors to achieve ideal rated RPM, ranging from 3.4mm to 45mm. This makes it suitable for ideal operations in small spaces.

- High Torque. The ZHAOWEI high torque low RPM planetary gear motors with 4-stage transmissions can be used for relatively heavy loads, which are able to sustain intermittent or sudden load changes.

- Low backlash (≤2°) makes high precision possible, which is suitable for precise positioning applications. This helps to prolong the service life and improves operating performance.

- High Efficiency. The efficiency can reach up to 90%.

- Low Noise. Reliable cutting & meshing technology reduces the error of gear teeth, enabling low-noise gearboxes.

- Wide Applications. Different RPM are needed for different applications. ZHAOWEI provides a wide range of choices.