How to Distinguish Between Brushed Motor and Brushless Motor?

A DC motor is a motor that can transform DC electric energy into mechanical energy. There are two types of DC motors, brushed DC motors and brushless DC motors.

Brushed DC Motor

A brushed DC motor consists of a stator (the static part), a rotor (the rotating part), and a brush. There are magnetic poles on the stator and windings on the rotor. After electrifying, a magnetic pole is formed on the rotor, and there is an angle between the magnetic pole of the rotor and stator. Through mutual attraction of the stator and the magnetic pole of the rotor, the motor rotates.

The coil portion of the brushed motor rotates, while the brush is used to make contact with the commutator (copper head) in the winding for the coil to contact electricity and change the direction. The brush can be worn down during rotation, which means it needs to be replaced every so often.

Because the commutator can be worn during use, the copper head needs polishing to stay smooth, and the contact area of the brush and copper head needs to be expanded to improve efficiency. For this reason, maintaining a brushed DC motor can be quite troublesome.

A brushed motor isn't commonly used in multi-axis aircrafts, though a coreless brush motor is sometimes used in some light four-axis devices. The rotor of a traditional motor is formed by winding coils in an iron core, while the rotor of a coreless motor consists of a cage woven of coils without an iron core. It’s light weight (since it has no iron core) and has a quick response due to large rotating inertia and energy conversion.

The shortcomings of brushed DC motor:

A. The friction between the brush and the commutator causes low efficiency, loud noise, a rise in temperature, and service life several times shorter than that of a brushless gear motor

B. The brush needs to be changed regularly.

C.Low efficiency and output power for high resistance

D. High interference since the friction between brush and commutator can cause sparks

The characteristics of the brushed motor:

A.Good performance and high torque

B. Prices are lower than that of a brushless motor

C. Due to the lack of electronic parts, no influence of sensor interference.

Brushless DC Motor

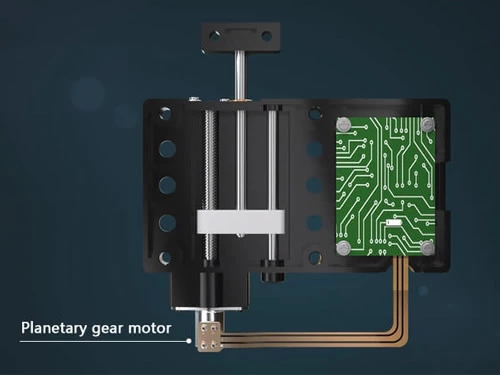

The coil part of the brushless gear motor is static, and the rotating part is a rotor that contains a magnet. In this situation, three groups of coil and brushless electric modulation are required to generate varying magnetic fields by continuously changing the current direction of coils and driving the magnet rotor to rotate constantly. A brushless motor requires brushless electric modulation to work, while a brushed motor can rotate by connecting the wire to the positive or negative of the power supply.

The shortcomings of the brushless motor

A. Brushless electric modulation is required to work together, making the price higher than that of the brush motor

B. Reliability is influenced by electronic parts. The motor will fail to rotate when the sensor is disturbed.

The characteristics of the brushless motor:

A. No friction between brush and commutator, low noise, small vibration, less heat generating, long service life

B. No need to change the brush, easy to maintain

C. No sparks caused by the brush, less interference.

D. High torque, good performance at medium and low speed, high starting torque, and small starting current.

In addition to selling standard products, ZHAOWEI also provides design, research and manufacturing for customers based on their specific needs.