Micro Transmission Systems Empower New Engines for Robots in Post-pandemic Era

The recent economic development from AI robots has seen improvement , but the industry is not getting the response it’s expecting. COVID-19 is showing us the potential of robots in the post-pandemic era. The robotics industry, however, still relies on our breakthroughs in the R&D of some key core technologies, the increase in the localization rate of key core components, the reduction of costs, and the rapid iterative update of some algorithms and model functions.

Post-pandemic, many companies have been trying to figure out how to reduce costs while increasing efficiency; as the labor force is aging, and wage costs are rising. It is difficult for factories to continue optimizing production costs. Intelligent robots are able to improve the labor efficiency of workers, and perform big data analysis to assist decision-making. This can improve the efficiency of input-output ratio. Therefore, artificial intelligence has become the gateway to starting a new stage of manufacturing cost optimization. In the post-pandemic era, how will robot gear parts manufacturers meet the needs of downstream customers, seizing development opportunities this time?

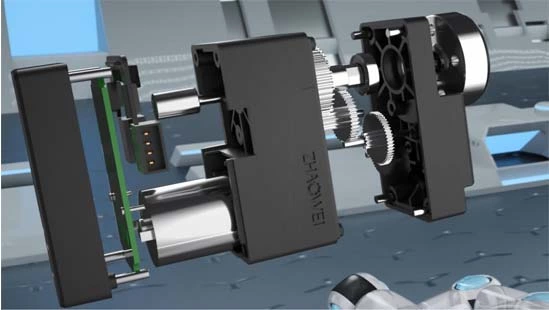

ZHAOWEI Machinery & Electronics Co., Ltd ( ZHAOWEI) works with robot manufacturers to create new engines for robots via micro-transmission systems and joint components. Based on our analyses of robot joint structures, and the design test of motion principle, we have optimized the structure of robot joint motors. This allows the robot joint servo motor to have better flexibility, high torque, and be small in size, which enables better movement in small spaces. ZHAOWEI combines market demand with product R&D to continuously meet the differentiated needs of clients towards robotics.

The motor is a key link in the intelligent robot industry chain, and the robot joint is one of the components applied to the robot arm. Given the extensive use of robot joints, the robot arm constantly needs to be upgraded, which also brings higher requirements to the motor. Existing robot arm motors generally have issues including various specifications, small batches, poor parts versatility, high cost, and unstable quality and reliability. The range of tasks that a robot arm can complete is limited by its own mechanical structure. Using robot gear DC motors to optimize the structure of the robot arm is one of the key technologies to solve this problem. ZHAOWEI works with the robot manufacturers to optimizes the structure of robot arm joint motors.

Through the development of abrasion-resistant material technology, processing technology optimization, lubrication technology, assembly technology, reliability and life testing technology, and the exploration of transmission mechanism, ZHAOWEI strives to develop a high efficiency and low-weight reducer (gearbox), suitable for robot arms. The reducer is durable, stable, and has high precision, which avoids the abrasion and winding problems of the robot arm’s control cable. This better meets the flexible transmission requirements of robots, and greatly improves the performance of intelligent robots, including perception and recognition, mechanism and transmission, control and interaction.

The International Federation of Robotics (IFR) points out, “2017’s industrial robot sales increased by 30 percent year-on-year to 381,335 units, the fifth year of record growth.” Asia remains the world’s strongest growth market for industrial robots. According to the report, about 137,900 industrial robots were sold to China in 2017, 59 percent more than in 2016. This was more than the total sales volume of Europe and the Americas (112,400 units) combined.

At present, market demand for robots is continuously increasing, forcing new demand for robot joint reducers to increase at a compound annual growth rate of nearly 20%. It is estimated that global market sales of precision reducers will exceed RMB 60 billion by 2025. The robot joint motor is one of the core components of the robot, and downstream system integration is key to the global commercialization of robots.

At present, there are only a few robot reducer manufacturers with large-scale production capacity and reliable product performance in the world, and most of the global market share has been taken by Japanese companies. Although Chinese robot motors are cheap, with shorter delivery periods, there is a big gap in product performance between China and other countries. Most Chinese reducers are used for middle and low-end robots, and are unable to meet the requirements of the high-end robot market. Under these circumstances, the ZHAOWEI robot servo motor meshes with the big gear on the output shaft through the small gear on the input shaft, reducing the speed, and increasing torque to improve dynamic performance.

In the robotics industry, 4G networks are unable to fully meet the needs of robots for large amounts of data calling and processing. However, with the rapid development of 5G technology, wireless high-speed data transmission has become possible. Low -atency and high-bandwidth mobile networks enable us to use cloud technology in the robotics field. Through continuous training, and the evolution of cloud brain artificial intelligence algorithms, the intelligence of the robot can rapidly improve, making it more adaptable and expandable. The robot connects to the cloud brain through 5G network to acquire general intelligence, and finds an ideal way to perform tasks and navigation. This avoids repeated development, saves expansive labor and material resources, and reduces the development cycle. The dawn of manufacturing intelligence is emerging, and artificial intelligence technology competition is increasing. Companies must think about how to "light up" industrial artificial intelligence in order to gain an advantage in this "light chaser" race.