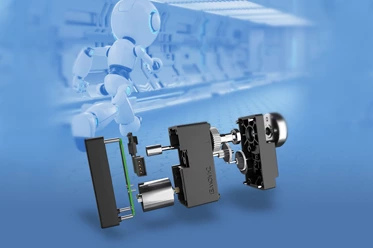

In order to meet the needs of various types of robot joints developed with modern high-tech, ZHAOWEI provides different gear motor specifications of robot joint...

Robot Vacuum Cleaner Motor Drive Motion

Advancements in technology, and the economy, has given researchers more opportunity to bring more convenience to humans. First launched in the 1990s, the robot vacuum cleaner frequently collided into objects, and failed to clean corners. Recently, technological advancements has allowed companies to optimize these machines by understanding market demands. Robot vacuum cleaners have come a long way, and some have functions that include wet mopping, anti-dropping, anti-winding, anti-twining, and mapping. These vacuum cleaner functions can be enabled by the gear drive module from ZHAOWEI, a leading motor manufacturer.

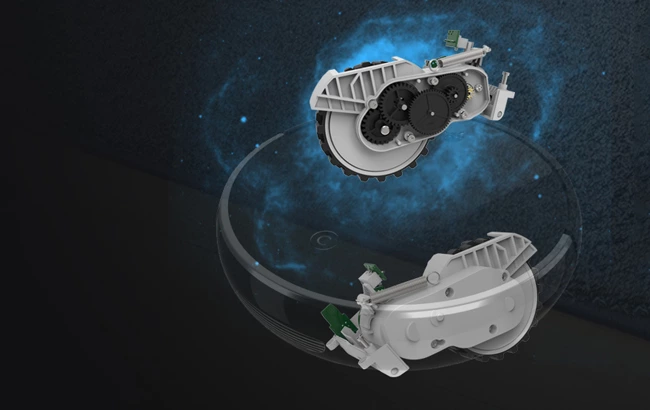

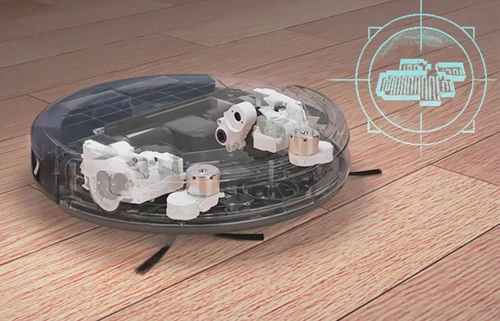

Robot vacuum cleaners function with wireless network technology and AI. The body of the robot vacuum cleaner is generally round or D-shaped. The main hardware of the vacuum cleaner includes the power supply, charging equipment, motor, mechanical structure, sensor, etc. The robot vacuum cleaner relies on brushless motors to move while vacuuming, which are controlled by a wireless remote control. Built-in sensors and AI algorithms make detecting obstacles possible, achieving capabilities which include anti-collision and route planning.

Robot Vacuum Cleaner Motors Optimized by ZHAOWEI

Round-shaped Robot Vacuum Cleaner

Robot Vacuum Cleaner Motor– Playing an Important Role

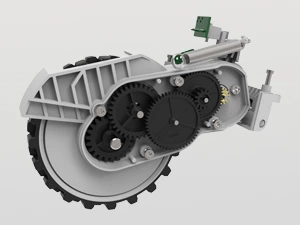

Parallel-shaft Gearbox Module

Outlook

Statistics from Statista shows a clear, upward trend in the global demand for robotic vacuum cleaners from 2015 through 2025. In 2018, the global robotic vacuum market was valued at 1.84 billion U.S. dollars; the market value is forecasted to reach 4.98 billion U.S. dollars by 2025. We can easily predict that the robotic vacuum cleaner will have an increasing market demand.

The robot vacuum cleaner motor in the image was developed and designed for a specific client, and is only shown here as an example. ZHAOWEI can design, develop, and manufacture products according to the requirements of each client. It is not for other commercial purposes, or sold to a third party.

In addition to robot vacuum cleaner, we also provide solutions for robot joint, intelligent robot nurse, educational robot smart base, model airplane, robot head rotation, coding robot and automatic feeder.