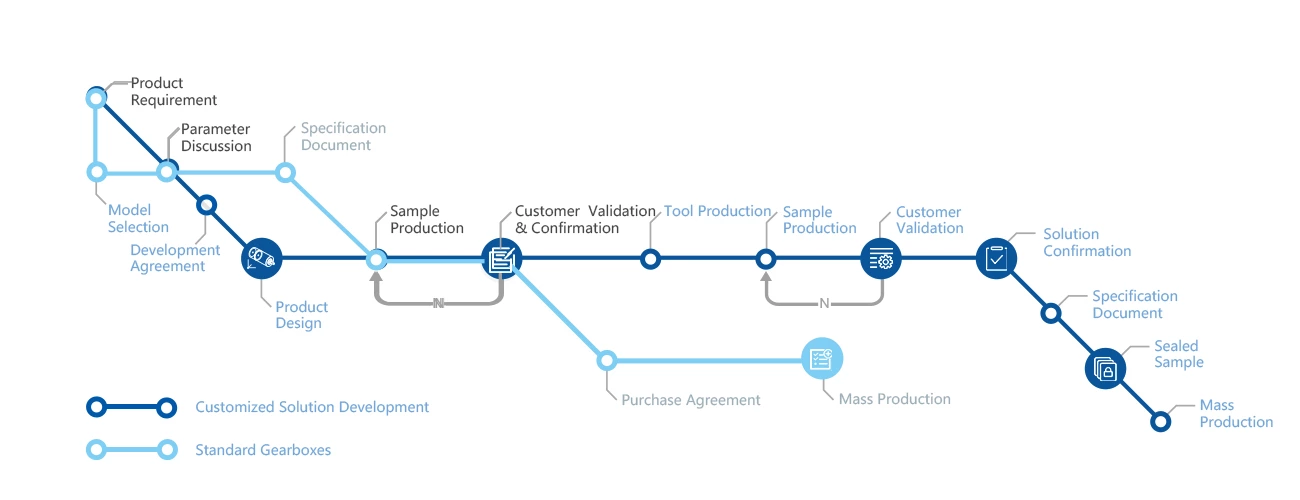

Customisation

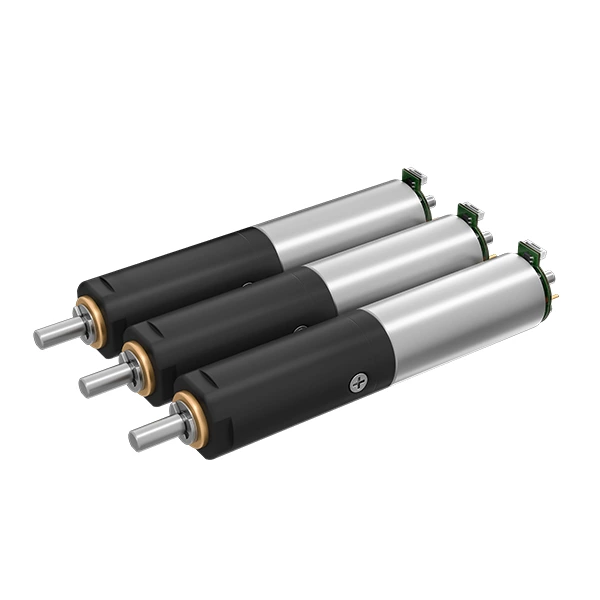

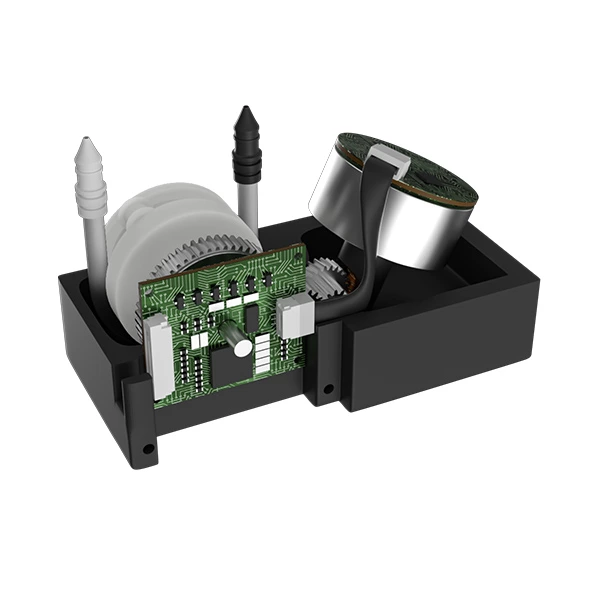

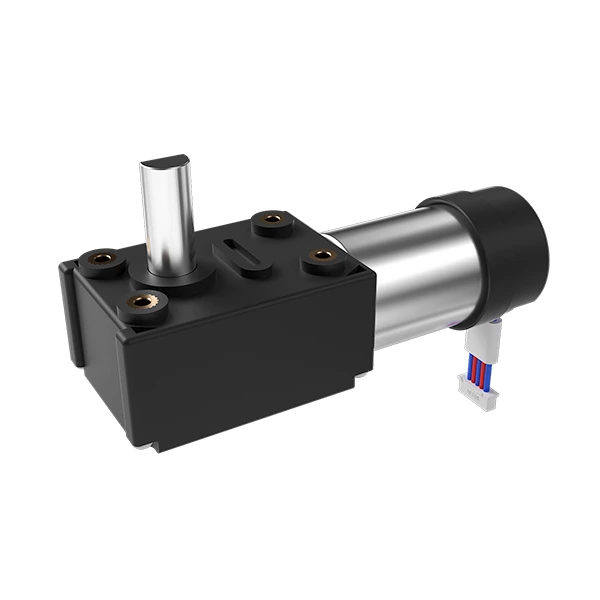

In depth basic knowledge is the basis for the customized and application-specific development of components, assemblies and gears. For us, product development stands for the function and process-adequate selection of materials, dimensioning of the assemblies and gear design. Manufacturing of large series is guaranteed through the consistency given from basic development to large serial production.